Extend the life of your motors and keep your operations on-track. TMS services all varieties of traction motors for the railroad, mass transit, industrial, and mining industries.

With our experienced team, repairs, rebuild and rewinding capabilities along with our extensive inventory reduces delivery times to give you optimal performance from your motors.

TMS Services and Programs

- Repair and Rebuild customer motors

- Unit Exchange (UTEX) TMS will supply a unit in exchange with customer supplied core.

- Running Take Out (RTO) Unit was running when removed from equipment.

- Re-Manufactured (REMAIN) unit is rebuilt with new field coils, re-filled commutator, rewound armature, and rebuilt brush holders

- Electrically OK (E-OK) unit has a meggar reading of 1 meg ohm or higher

TMS Repairs, Rebuilds, and Rewinds. Basic Overhauls Consist of:

- Motor Disassemble, Inspect and Advise repair cost (DIA)

- Preform electrical and mechanical dimensional checks

- Detailed Analysis of repairs to OEM standards

- VPI impregnate and bake armatures

- Computerized balancing

- Bearing replacement

- Brushes and brush holder repairs and replacements Testing

- Pinion Installation

- Paint motor frames

TMS Capabilities and Equipment

- Disassembly and assembly bays

- Inspection bay

- Parts washer and steam cleaning

- Furnace

- VPI Systems

- Banding Lathe

- Tig Weld Station

- Load Testing Station

- 600 Ton Capacity Press

- Bearing Press

- Small and large parts Lathe

- Horizontal and Vertical Boring Mills

- Mag Particle Testing

- Automatic Undercutting Machine

- Coordinate Measuring Equipment and QC Lab

- Balancing Equipment

- Sandblasting and Painting

- CNC Axle Lathe

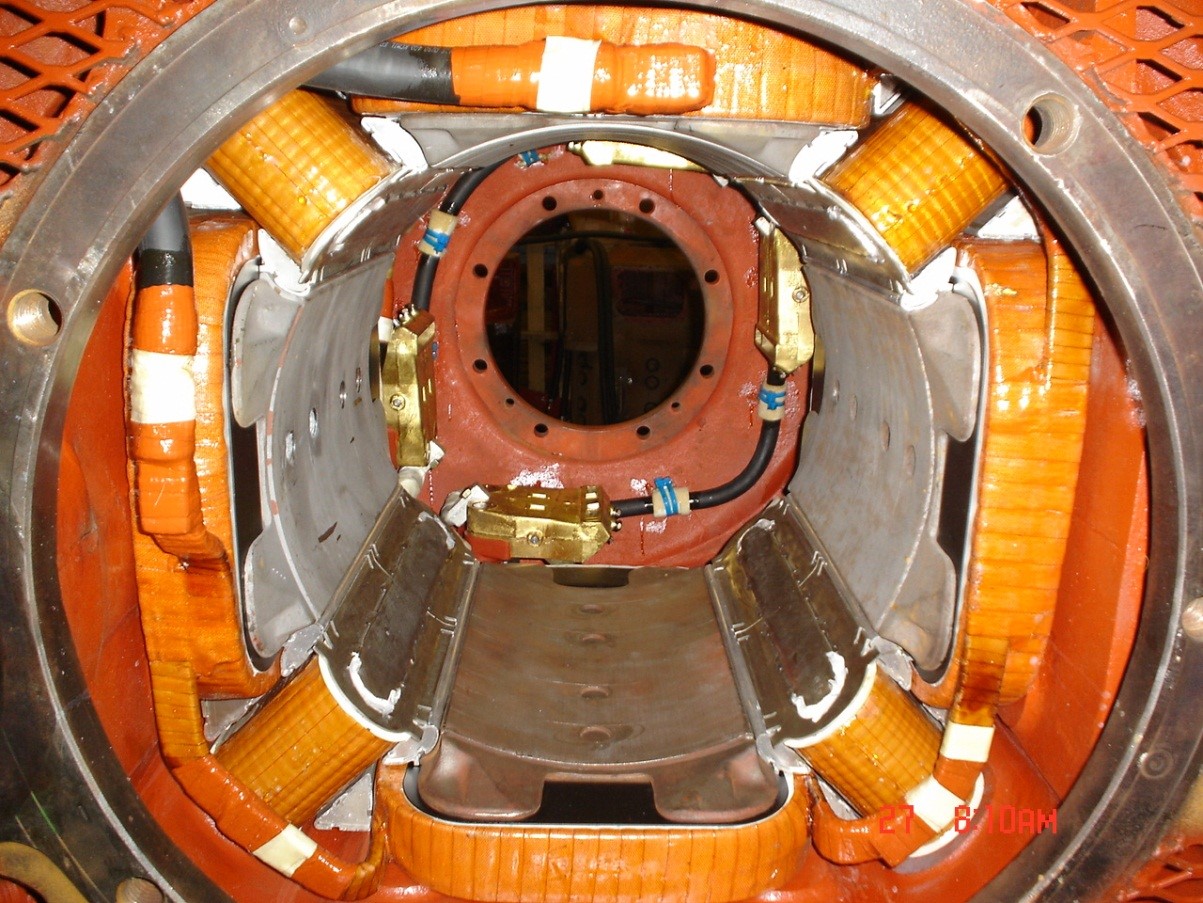

- 752 Traction Motor

- 842 Traction Motor

- 843 Traction Motor

- D77 Traction Motor

- DC Traction Motor

- DC Traction Motor

- DC Traction Motor Armature

- DC traction Motor Frame

- Shipping Traction Motors

- Generators

- Generator Diode Pack

- Generator

- Generator

- Generator